Ethan's MIT Maker Portfolio

HomeA Foreword

This is a collection of images and descriptions from the maker portfolio

that I used to apply to MIT. I haven't

edited it too much but its a good overview of some of

my previous projects.

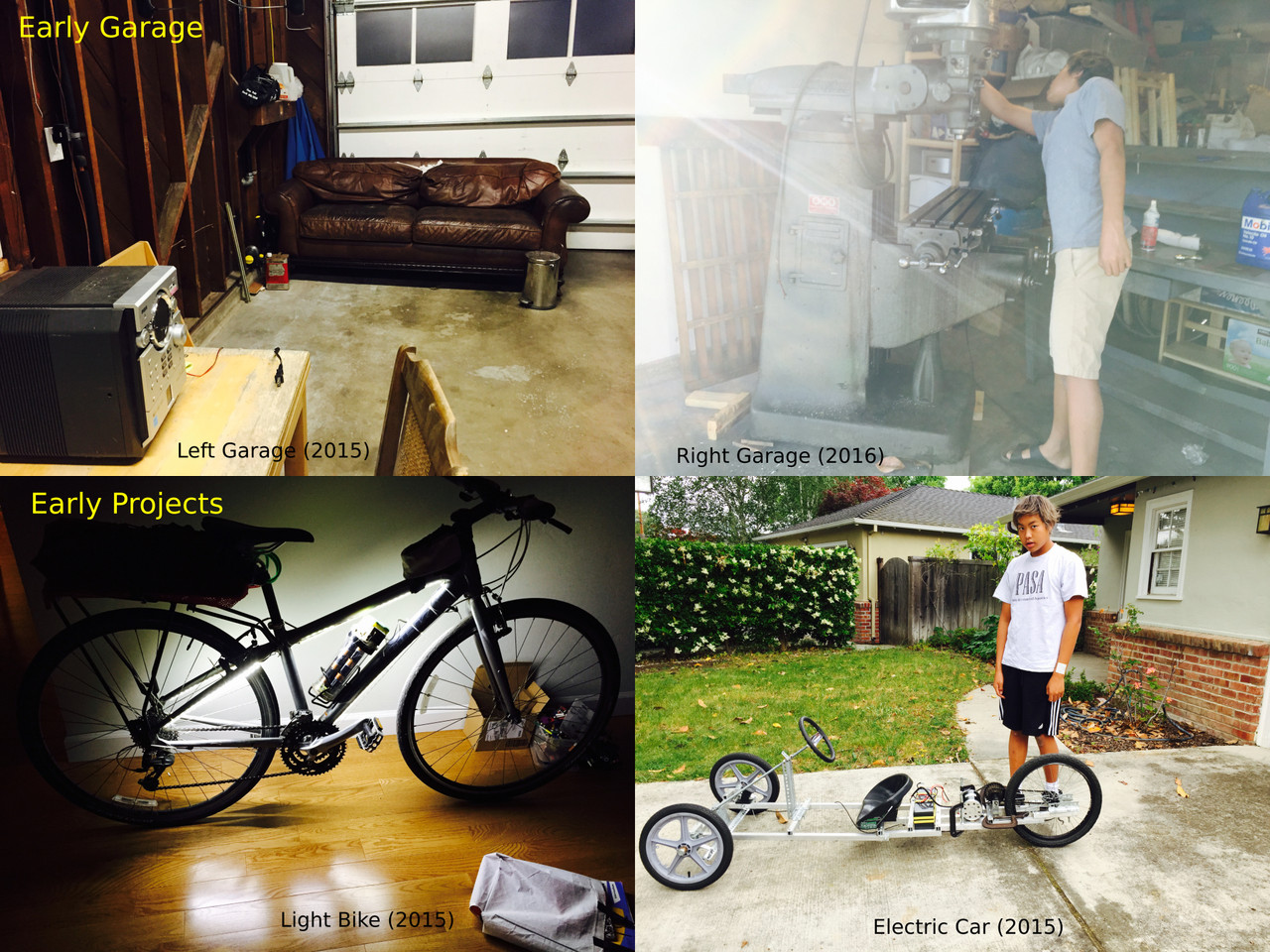

A long time ago...

|

Hi! I’m glad you could stop by. I’m Ethan! |

Projects!

Belt Grinder

|

To get better at using the mill and lathe, I

turned to Youtube for instruction. I watched hundreds and hundreds

of making videos on all sorts of projects. In many

of these, it seems that the presenters were building or

had built their own tools — and among these, belt

grinders were quite popular. So, as my first “big” project,

I decided to build one too. Drawing on inspiration from

all the different videos, I came up with this design.

It uses crowned pulleys in the back to keep the

belt on the pulleys and a door hinge and spring

assembly for fine tracking adjustment and tension. I probably went

overboard with the amount of solid aluminum stock, but hey,

if I have a mill, I might as well practice. |

Pedestal Grinder

|

It turns out, I really like making machine tools.

After some browsing on Craigslist (where all the machines were coming from),

I found this grinder for $50.

At that price, I could probably make a profit selling the motor and scrapping the cast iron.

But instead, I thought I’d improve it a bit. |

|

And this is what I ended up with!

There wasn’t a straight path for a belt from the new motor location to the spindle,

so I added some idler pulleys to redirect the belt.

To support these, I added some braces connecting the grinder frame directly to the motor mount.

Keep in mind that the vast majority of these projects were designed pencil on paper.

I only really started CAD with the CNC project and more complex projects after that. |

Supermax Milling Machine

|

Ah, the Supermax.

This is one of, if not the biggest tool repair/modification I’ve done to date.

As with the grinder, this was a cheapo craigslist find.

The seller said the computer controller (CNC) system didn’t work (ok, no biggie right?).

When I got it home, turns out neither did the spindle or the head (nothing spun).

The machine base, however, was in near perfect shape (less than 0.002” backlash),

which justified fixing the rest. |

|

Well, there’s never just one thing wrong.

On the first test run with the new spindle, smoke shot out the top of the motor

and the machine roared like a jet engine (not good).

Luckily, the smoke was just the belt slipping on some loose oil.

But the roar? I had no clue. |

|

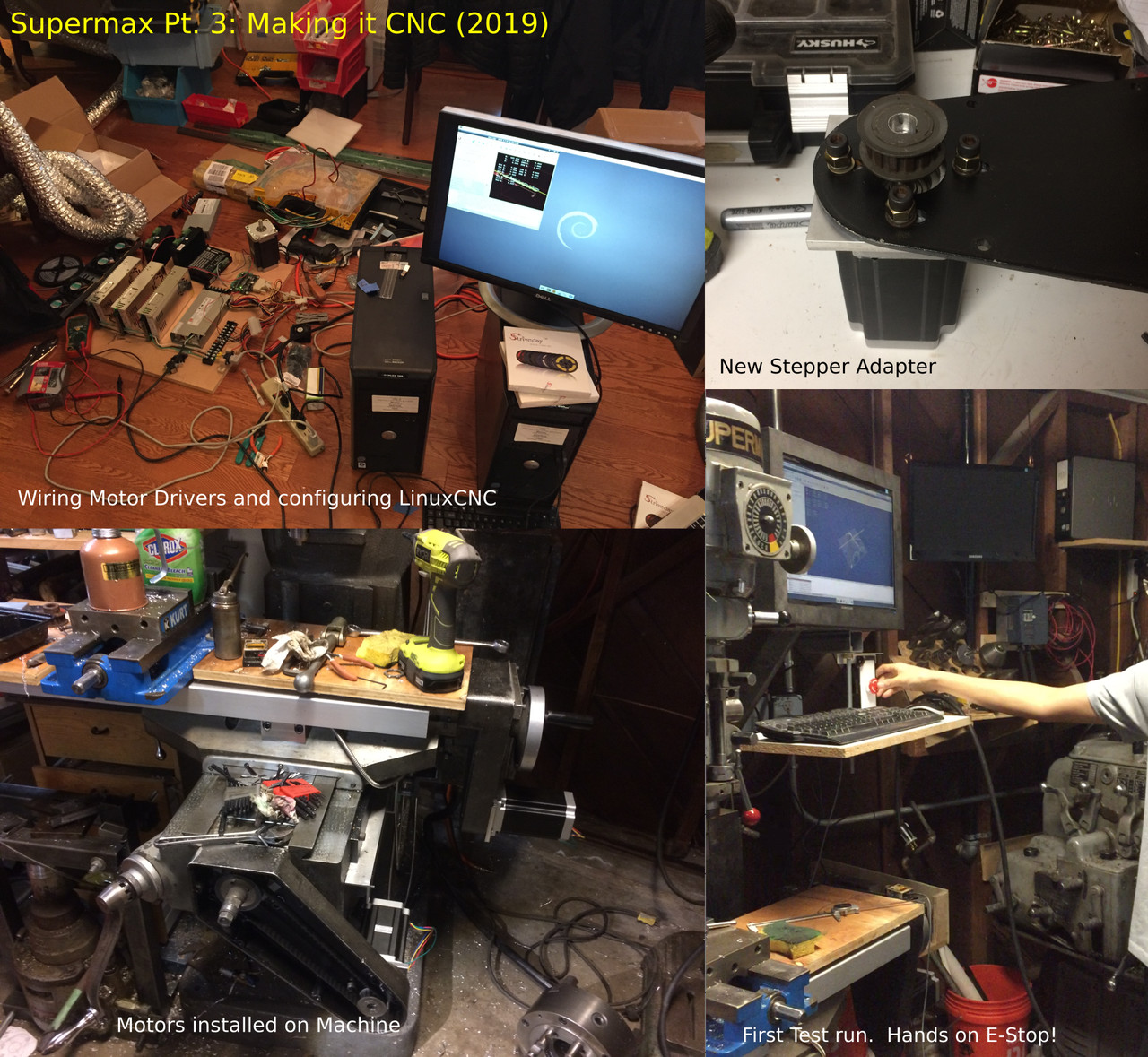

At this point, the Supermax worked perfectly

as a manual mill but I never was able

to fix the old computer system. Eventually, I opted to

convert the machine to run on Linux CNC (a free CNC

driver os) and to switch out the old motors and drivers

for newer steppers. This was partially intended to be a test

run for designing and setting up a CNC system (for the

large CNC, next). While I started out with no clue

how a CNC even works, everything turned out alright and the

machine moves in accordance to the computer. |

|

And it’s done!!! It’s been almost three

years (75% of my time as decent maker) but

I’ve managed to take this broken machine and turn it

into a fully functional two axis CNC. On the right,

you can see some projects and job shop work I’ve

done with the mill. |

The CNC

|

A long time ago, I got a CNC router for Christmas.

It worked alright, one in ten times. A few

years down the road (present time) I’ve gotten

it to work better, but it’s never been well

suited for my needs. |

|

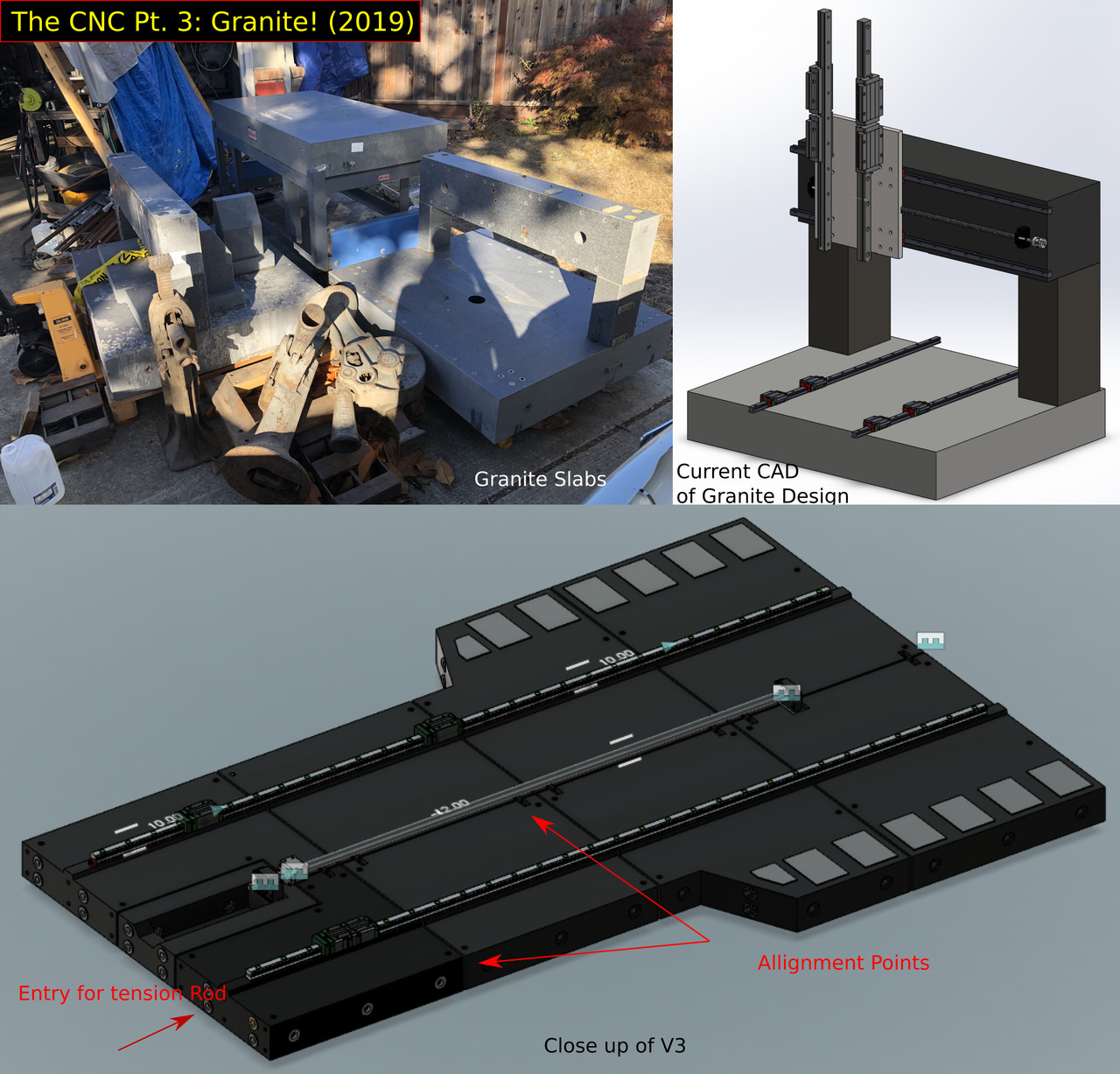

Originally, I was planning to make the CNC from concrete for

its low cost and high dampening properties. As I did more

research, I concluded that concrete exhibits low dimensional stability, and

that a similar substance utilizing epoxy as the binder (epoxy granite

) is favored in the machine tool industry. I also found

a variety of forum posts online about optimal compositions of epoxy granite,

but no precise values. This led me to conduct my

own mixture tests, using low viscosity epoxy and a mixture of

sand, glass nanospheres, and gravel as my aggregates. I

also tested how well steel inserts could be cast into epoxy granite

blocks (pretty well actually). |

|

I was preparing to make the epoxy granite machine when my friend’s

father (where the motor came from) offered me 8000lbs of

precision granite surface plates (the holy grail of precision machine tool

bases). I couldn’t resist, and had them delivered

to the garage. Unfortunately, this means that the machine must

be designed around those new plates. Unlike the other designs,

I’ve been doing the granite CAD in Solidworks. It

’s quite different from Fusion, but I really like all

the different parameters, the file system, and how well it

does with larger models. |

E-bike attachment

|

We will now leave the world of tools behind and instead look

towards electric vehicles. |

|

As with the belt grinder, this attachment contains excessive aluminum (

See the theme here?) and can probably survive a crash at

25mph (how fast it goes) unscathed. The motor is

from an electric scooter that I was given and the rest of

the electronics are off ebay and amazon. |

Electric Shopping Cart

|

You know, shopping carts are pretty slow… We can change

that. |

|

I basically shoved the shopping cart in a corner for two years

while working on other projects. Until, one of our robotics

team mentors said his work (Department of Water Management) had

a bunch of broken Lime-E and Bird scooters that had

been thrown in the creeks that he could give me. I

couldn’t say yes any faster. |

|

And it turned out really well! I figured out that I

could steer similar to how a bike can be ridden no handed

by angling a single front wheel forward. This system however was

susceptible to oscillations (caster wobble) and made the cart near

uncontrollable at certain speeds. To combat this, I added the

bar to the front axle (shown previously) to increase the

system’s moment of inertia. This worked to a degree,

but still produced oscillations (now at a different speed).

I then thought about how large towers combat oscillations with a liquid

filled damper. The first bottle of liquid I found was a

coke bottle, which, once installed, worked so well

that it became the permanent damper. |

Conductivity Meter

|

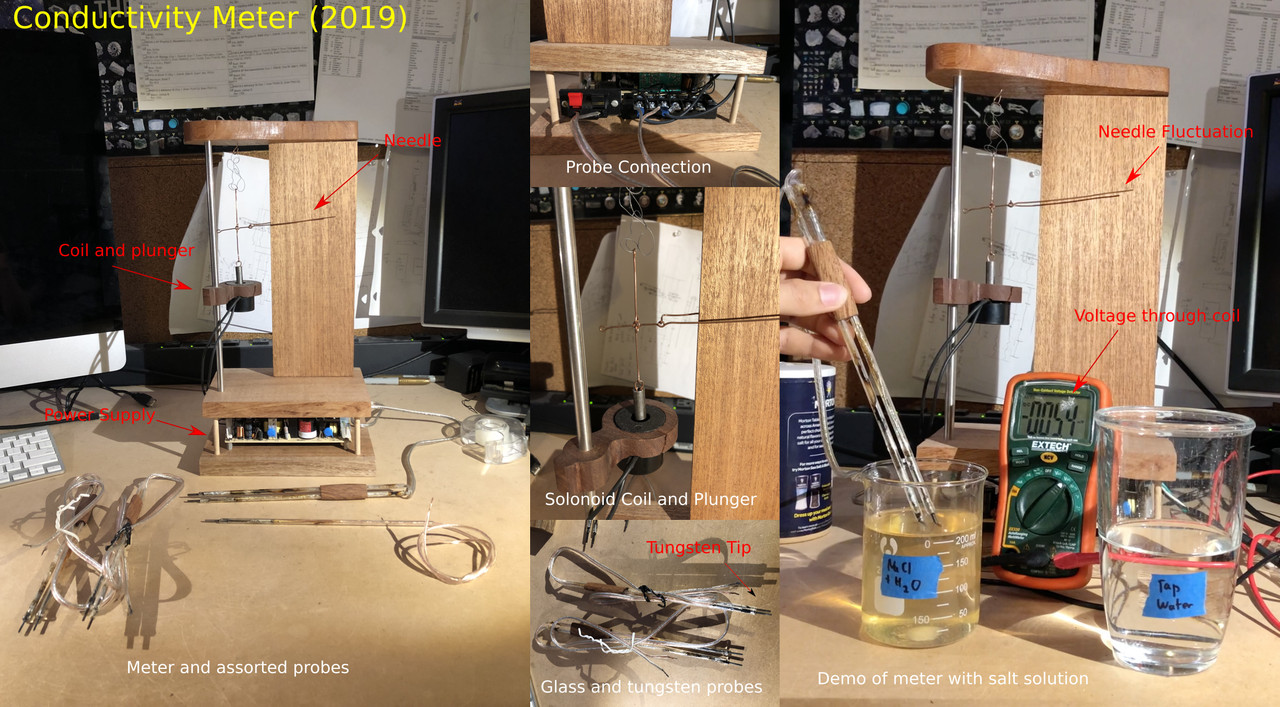

Now, we arrive at the “school” projects. This

was from an AP Chem extra credit assignment (build a conductivity

meter). I could have done something with tin foil and a

lightbulb, but I really wanted to try making glass and tungsten

probes (relatively inert materials) and see if I could mimic

the old style ammeters with a coil. That led to this

design. I played around with fusing tungsten inside some glass tubes

for the inert probes and with trying out some woodworking techniques on

the frame to get that vintage vibe. I also discovered how

much fun copper wire is for making little levers and stuff.

The meter works well for differentiating between non-conductive, moderately

conductive, and uber conductive substances but (expectedly) doesn’t

tell the operator too much else. At this point in

shop history, I’d gotten pretty competent at making random

things; so, this was more of a “let your imagination run wild” project. |

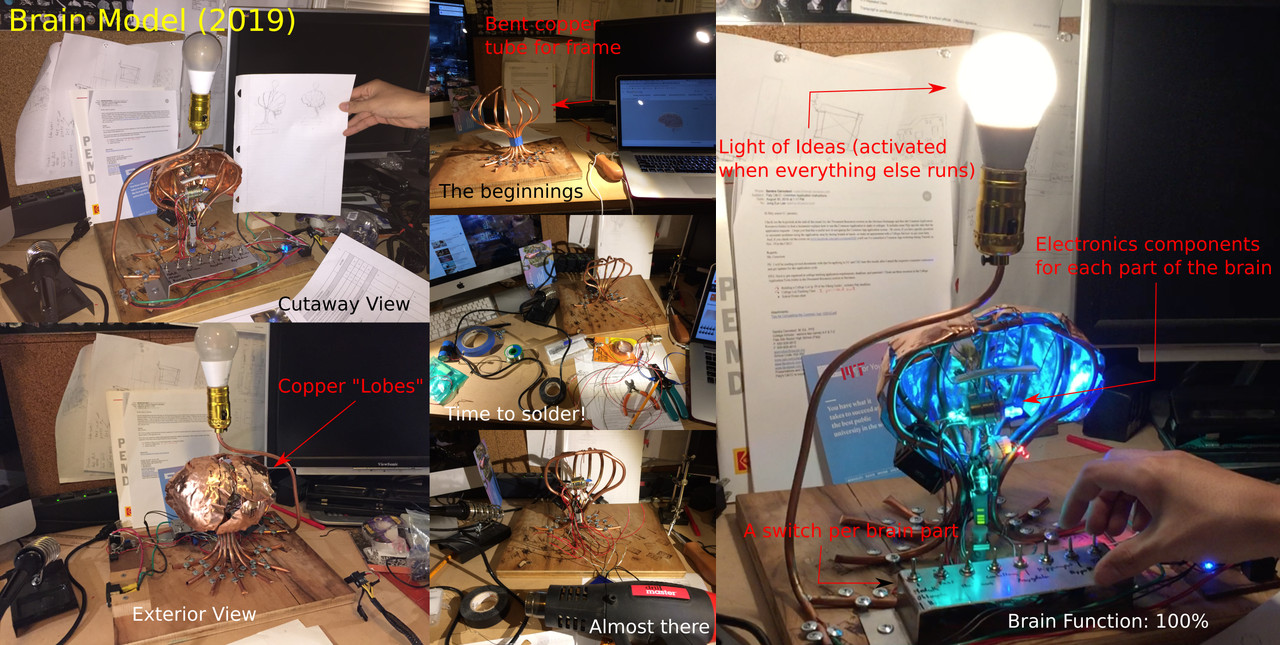

Brain Model

|

The more recent of the school projects, this was for the

“build a brain” AP Psych assignment. Again, something

simple like play-doh would have worked, but where’

s the fun in that? I really loved working with copper

in the conductivity meter, so this time I went for a

full copper frame. The sheets on top were hammered to represent

each lobe of the brain, while electronics components inside represent (

in shape) each part of the brain. A switchboard at

the base controls each part individually, allowing the user to associate

a labeled switch with the corresponding brain part. And I couldn’t

resist the idea *lightbulb* trope. So,

when all the switches are turned on, the light turns on

too! (via a relay). Like the conductivity meter,

this was a “wild imagination” project. It was a

ton of fun and something I couldn’t have dreamed of

doing three years prior. |

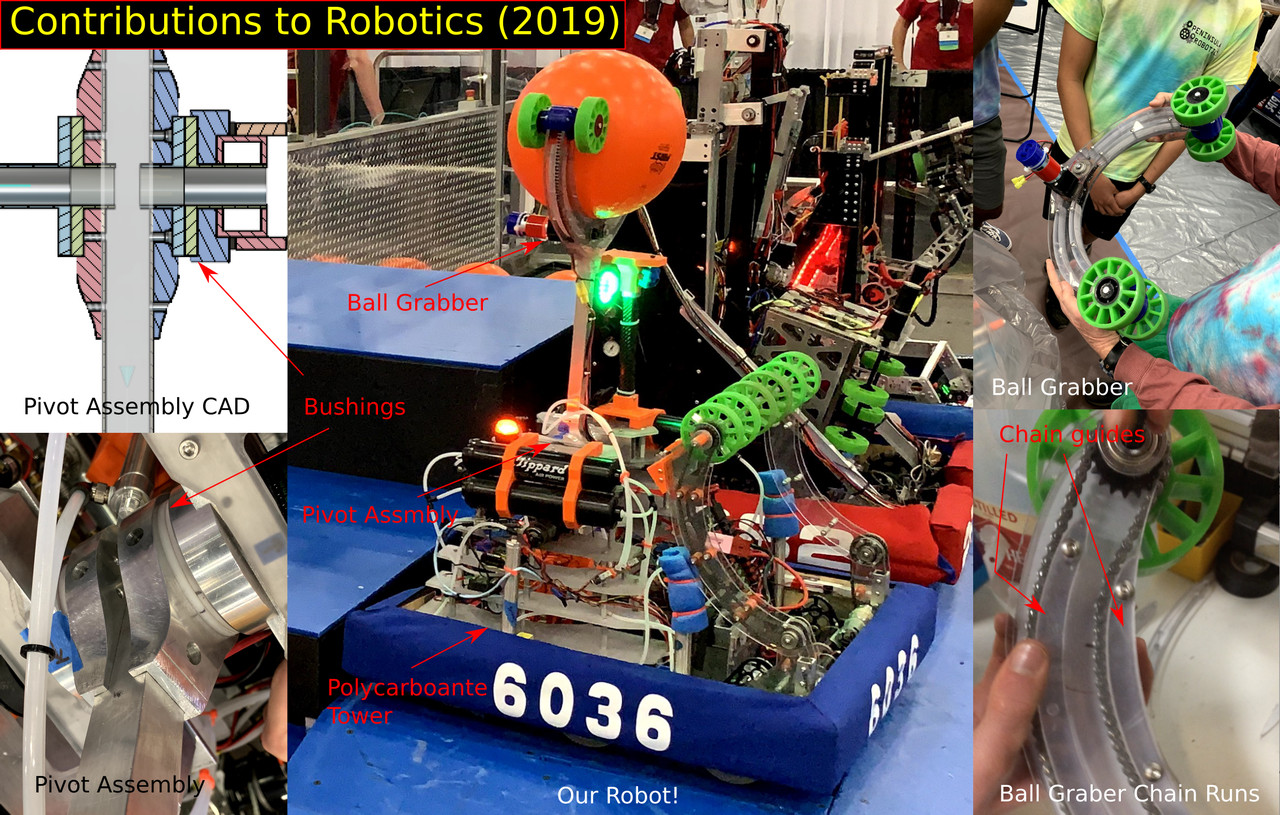

Robotics in the Shop

|

In parallel to my own projects, I was (and still

am) a very active member of an FRC robotics team.

We are not affiliated with a school, and when I joined

four years ago, worked out of a residential one car garage

limited to hand tools. Once I had set up shop,

gotten and set up more equipment, build tools, and figured

out how to run everything, I started inviting the team over

to machine. It’s pretty nerve racking, demoing a

huge machine tool in front of an audience. But watching everyone

’s smiles as they make their first cuts (as I

did years prior) makes the nerves more than worthwhile. Now,

I’m (along with the responsibilities of being build

captain) in charge of all machining that goes on in the

team, whether that be training members how to machine, or

organizing 5-7 teenagers into running all sorts of machine tools

simultaneously. |

|

Given that my FRC team is also on the small side,

I’ve been given the opportunity to design and machine certain

assemblies from start to finish. This past year, I designed

the main pivot and pivot support for our arm, using custom

nylon bushings in an aluminum housing for the bearing element, and

pushing for the layered polycarbonate tower as a more compliant way to

support the arm (as opposed to a welded structure). I

ended up machining the pivot assembly as well due to the relative

complexity of the parts. |

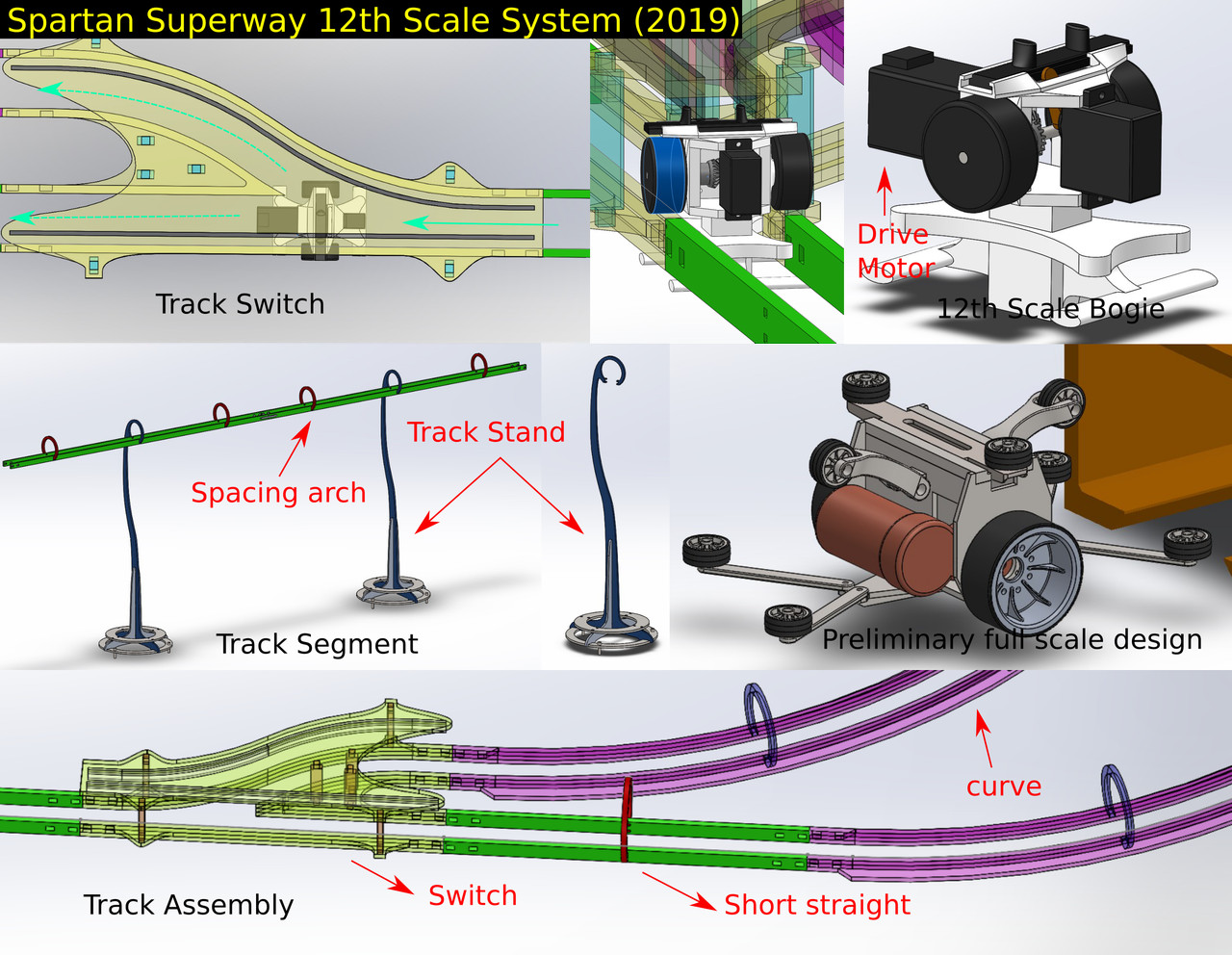

Spartan Superway

|

Around summer 2018, I met Professor Furman of the San Jose

State Spartan Superway Project in a truly serendipitous fashion. At some

point, he mentioned a problem with their track, to which

I sat down and offered a potential solution. That solution got

me invited to conference weekly with the project and more recently,

work with him and other college students over the summer. During

this time, I designed and cadded a modular 12th scale track

and bogie assembly, intended to be cut on the waterjet and

laser cutter. The bogie is designed to be 3D printed while

the protruding nubs serve as guides. This, along with the

CNC, is where I really dove into solidworks CAD and where

I started to dabble in using FEA for my projects. This

experience is also my first time using my making knowledge and applying

it to a much larger and more significant project. Here is

a link to more details on the Superway and my work if

you are curious: https://jacqueshariel-ango-spartansuperway.blogspot.com/ |

Kuprion Inc.

|

When I work, I tend to keep the garage door open

. Thus, a decent portion of the neighborhood knows that a

machine shop lives in my garage. One day, I got

a knock on my door from a neighbor who works at the

copper nanoparticle startup, Kuprion inc. Apparently, they needed something

machined! Given that I’m a highschooler, I offered

1-2 day turnaround and a minimal cost. Well,

it seems they liked my work and, as such, have

been asking me to complete new jobs every now and then as

they get their copper production setup running. So far, I

’ve made some baffles, modified their reactor lid, designed

and built a reagent dispenser, and designed and built a motor

adapter. Considering that four years ago, I didn’t

know what a mill was, I’d say that designing

and machining for money is quite an improvement!

And apparently they think my work is pretty decent as well. |

Others

|

Well that sure was a lot of projects, right? Here

’s 16 more! Jk, I had the space so

I thought I’d include an honorable mentions list. Most

of these are just storage and organization for the garage. At

some point, I also made copper coils for my school’

s physics department and built a venus fly trap growing apparatus for

my room. I think it just goes to show how much

infrastructure is needed to actually get a machine shop to function and

how I’ve managed to optimize my garage for maximum space efficiency. |

Current Garage

| I can't find the pic :( |

And this is it! The garage as it currently stands.

These past four years have been a wild ride. I’

ve taken this garage from an empty room to a full fledged

machine shop. I’ve made parts for a startup,

worked on a college project, made custom machines, built fun

vehicles, gone overboard with school projects, and hosted and mentored

my FRC team. I’ve gone from not knowing how

a drill press works to designing my own CNC machine tools.

I’ve kindled my love of making and taken my projects

to the next level. Quite frankly, I’m proud

of how far I’ve come. And as the next

stage of life approaches, I’m eager to make so much more! |

Some background for curious people (Circa 2019 and not entirely accurate)

What do I make

I make machine tools, relevant machine shop accessories (shelving, tool storage, tables, etc), electric vehicles, novel vintage style science electronics, and parts of FRC robots. The machine tools are either entirely custom or a modification of an older or broken machine. Of course, to run machine tools in a garage, a certain degree of infrastructure is required. Thus, I’ve built some tool and material storage, along with workbenches. And as more of a “get loose” style of project, I like making electric vehicles using reclaimed e-scooter and e-bike electronics. In addition, given the small size of my FRC team, I’ve had the privilege of making certain assemblies from start to finish. And, sometimes, in school, we are given some open ended task like “build a brain model”. For these, I like to go retro and design something fun using wood, copper, and vintage looking electronics.

How do I make

I’ve turned my residential garage into a full blown machine shop. Using machine tools I’ve built, restored, or found on Craigslist, I machine my creations from raw steel and aluminum stock. On occasion, I will also weld (using an old Miller stick welder) steel tube together to make various machine frames. I use Solidworks CAD to design more technical projects (CNC mill), Fusion 360 CAM to drive the CNC router and retrofitted mill, and paper and pencil for the get loose projects. No one else in my family is a big “maker ,” thus 95% of what I know has come from watching machinists, woodworkers, and fabricators on Youtube . By peering into their workshops for hours on end , I embark on a “virtual apprenticeship,” obtaining tips of the trade from the best in the business.

What is my most significant project?

My most significant project is my (in progress) custom CNC mill. I tend to make projects based off some initial curiosity (Hey, I got a cnc router kit but it doesn’t work very well, let’s make it better!) and then go from there. This project started out innocently enough (let’s weld a new frame, upgrade the motors, and be done). But then I decided I wanted a larger work envelope and better rigidity, which led to the question of manufacturability, which led to research in epoxy granite machines, which led to epoxy granite mixture testing, which led to me getting free 2000lb granite surface plates from a friend, which leads to the current state of the project at CAD of the granite design. This meandering of exploration through all the fascinating intricacies of a project is the epitome of why I make anything. And why, although yet to be completed, my CNC project is so meaningful to me.